A plant-by-plant strategy for high-ambition coal power

2023.12.4 coal-fired power plants without carbon capture and storage (CCS) also peaks in 2020 and then continues to decline by more than 90% in 2040 and 2050 and

consulter en ligne

Progress and prospects of innovative coal-fired power plants

2019.4.1 Concerning the existing coal-fired power units, which are responsible for peak shaving, possible strategies for enhancing flexibility and operational stability are

consulter en ligne

Coal: Energy for the Future - The National Academies Press

The framework is based on projected scenarios for future energy demand and markets for coal technologies, taking into account likely future environmental requirements,

consulter en ligne

Coal transportation and logistics planning for now and the future

2023.1.1 The overall coal chain includes the transport and handling of coal from the mines to rail, to the export port, onto ocean transport, and then to the end user—normally

consulter en ligne

The future of coal supply in China based on non-fossil

2021.4.1 Results indicate that: 1) China’s national raw coal production will peak in 2030 under the business-as-usual scenario, while it has already peaked under the

consulter en ligne

Quantifying operational lifetimes for coal power plants

2019.10.18 We show lifetimes of retired units (a) and the vintage year of existing units (b) and calculate global coal capacity under different plant lifetimes, compared to

consulter en ligne

A cleaner future for coal power plants and coal-reliant

2022.3.16 Repurposing coal power plants to renewable ones is a key consideration for the just transition. Alongside its social benefits, coal power plant repurposing also

consulter en ligne

Instrumentation and control in coal-fired power plant

2018.1.28 Coal-fired plants are the most widely used power plant today. They involve the combustion of coal producing high pressure (typically 2400–3500 psig, ~165–240

consulter en ligne

The next 20 are years crucial in determining the future of coal

2021.6.8 FULL STORY. Decisions made now will determine whether economies win or lose money as the coal industry changes over the next couple of decades. Countries

consulter en ligne

STANDARD DESIGN CRITERIA/ GUIDELINES FOR

2020.4.7 Annexure-2A Typical scope of work for coal handling plant 2- 23 Section- 3 : Ash Handling Plant 3.1 Introduction 3- 1 3.2 System description 3- 2 3.3 Design criteria and broad features 3- 6 3.4 Performance requirements 3- 20 3.5 Codes and standards 3- 24 Annexure-3A Typical scope of work for ash handling plant 3- 25

consulter en ligne

Thermal Power Plant: Diagram, Layout, Working

2023.7.9 The coal should be available in sufficient quantity nearer to the plant at a low cost. #2 Ash Disposal Facilities. There must be sufficient space to dispose of a large quantity of ash. #3 Space Requirement.

consulter en ligne

(PDF) Future Coal Processing Strategies for India

2017.11.6 The general practice in coal preparation plants (CPP) for metallurgical coal in India has been. desliming the plant feed at 0.5 mm a nd processing 13 x 0.5 mm in heavy media (HM) cy clones. (HMC ...

consulter en ligne

Performance optimization of 1800MT capacity stacker

2020.1.11 Performance optimization of 1800MT capacity stacker - Reclaimer in coal handling plant in 600MW/660MW sub/super critical units SN Dubey, Narendra N Dalei, Rajeev Sharma School of Business, University of Petroleum and Energy Studies, Kandoli Campus, Dehradun, Uttarakhand, India Abstract Stacker cum Reclaimer is the heart of

consulter en ligne

COAL HANDLING PLANT TERRACE BIN 1 REPAIR WORK

drawing which will be used as future statutory reference report for the assessment (Safe to use) of the terrace bin as stipulated in the OHSAct under construction regulations. ... used within the Coal Handling Plants: 3.1 Technical scope a) Further engineering assessment, analysis and design for repairs of the failed terrace bin 1, performed by ...

consulter en ligne

Coal Mining and Local Environment: A Study in Talcher

2017.9.5 In the era of 21st century, this belt has become an industrial hub. Along with MCL, a good number of coal-based thermal power plants, several heavy industries, coal washeries, and a large number of subsidiary industrial units have come up in the area. All these mining and industrial activities have caused rapid degradation of environmental

consulter en ligne

Coal handling along the supply chain - ScienceDirect

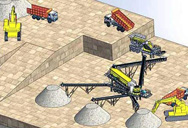

2023.1.1 A typical coal (preparation) flowsheet involves a series of preparation equipment, materials handling equipment, and auxiliary equipment, for example, sampling plants, dedusting units, utility systems, and others (Fig. 21.1).Download : Download full-size image Figure 21.1.

consulter en ligne

Quality Assured Maintenance Management For Coal

2015.10.8 be performed to help prevent future unscheduled shutdowns. Government mandated inspections and repairs could be accomplished during a shutdown, bringing a plant into better compliance. 4.1.1 Objective Of Maintenance Planing: - A plant is a place, where men, materials, money, equipment, machinery, etc., are brought together for

consulter en ligne

Coal Challenges and opportunities - PwC India

As on 1 June 2022, out of 165 coal-based power plants, 100 are running at critical coal stock. 5 Thermal power plant generation increased by 7.60% in April 2022 6 compared to April 2021, while the planned increment was only 2.15%. This coal shortage has been exacerbated by inadequate planning and demand forecasting.

consulter en ligne

Structural Integrity–Reliability Analysis of in-use Coal Handling ...

2022.8.1 Non-destructive testing (NDT) is effective in detecting surface as well as intrinsic faults in structures during production or in-service service life without destroying the originality of the test specimen. It is a tool that ascertains the viability of potential, behind sceptically for current and future use of material. The structural strength of the coal

consulter en ligne

Co‐firing of biomass with coal in thermal power plants:

2013.11.19 Biomass co-firing is widely considered as the most cost-efficient and easily deployed way for mitigating the CO 2 emissions from the coal power sector. Apart from policy and market benefits and bottlenecks, the implementation of co-firing in a coal-fired power plant is affected by several technical and environmental concerns.

consulter en ligne

Progress and prospects of innovative coal-fired power plants

2019.4.1 Furthermore, future trends for coal-fired power plants coupled with cyber-physical system (CPS) technologies are introduced. The development of advanced, coal-fired power generation technologies demonstrates the progress of science and is suitable for the sustainable development of human society. ... The former extends the fuel scope of

consulter en ligne

Operation and Maintenance of Coal Handling System in Thermal Power Plant

2011.1.1 The process of from big to small .Currently medium-sized power plant coal handling system used in coal crusher, structural characteristics can be divided Hammer, Impact, and other types of hammer ring, hammer coal crusher due to its large strengths, high-efficiency features, used more often. 2.2.1. a Operation and maintenance of roller

consulter en ligne

Automated Materials Handling for Coal-fired Power Plants

2014.3.11 The increased degree of efficiency of modern coal power plants calls for an integrated coal handling management system in order to secure the coal supply in the requested quantity and quality. In order to cover these requirements ABB has developed a modular management system as shown in Fig. 2. With the acquisition of Mincom, ABB

consulter en ligne

Coal handling plant in a thermal power generating station

2024.1.1 In a coal based thermal power plant, the initial process in the power generation is “Coal Handling”. So in this article i will discuss the overall processes carried out at a Coal Handling plant in a coal based thermal power generating station. The huge amount of coal is usually supplied through railways. A railway siding line is taken into ...

consulter en ligne

Performance optimization of 1800MT capacity stacker -Reclaimer in coal ...

Stacker cum Reclaimer is the heart of the coal handling plant. Without stacker reclaimer, no body can think, to survive the material handling system, stacker reclaimer has become the more important for the CHP life and for the safe operation of CHP ... S/R Availability CHP 1.2.2015 20.3.2015 Rs.430000/Conclusion Future Scope of work ...

consulter en ligne

The future of coal in India: Decarbonising the oft-maligned

Despite the resource’s vast polluting potential, coal remains the most dominant source of energy globally, responsible for 37% of global energy generation in 2019. India has also undertaken an ...

consulter en ligne

India's Jindal Power proposes to top Adani's bid for coal-power plant ...

NEW DELHI, Jan 12 (Reuters) - Jindal Power has proposed to top a bid by Adani Power (ADAN.NS), led by billionaire Gautam Adani, for a thermal power plant, two sources with direct knowledge of the ...

consulter en ligne

(PDF) Future of coal-based thermal power plants in India

2022.7.3 Future of coal-based thermal power plants in India. by Shaikh Shamser Ali, Ruchi T yagi, Nidhi M J and Atul Agarw al 118. Call toll-free 800-521-3044. Or mail inquiry to: University Microfilms ...

consulter en ligne

Morupule Coal Handling and Preparation Plant - Pentalin

2024.7.14 Our Flagship Coal Project in Botswana. The Morupule Coal Handling and Preparation Plant is Johdee’s flagship coal processing plant in Botswana. The project was completed in 2021 by Johdee. The Plant has a nameplate capacity of 250tph.

consulter en ligne

The Future of Coal In India: Some Scenarios and Key

2021.3.22 Key assumptions in the Rapid Technological Change Scenario: BAT implemented to improve energy efficiency in steel plants and maximization of scrap usage. Structural change and policy reduce the material intensity of the economy, in particular through existing trends like shared mobility. By 2040, H2 based steel production is

consulter en ligne

Energy Audit of Coal Handling Power Plant – IJERT

2018.11.7 Thus, by using this method of energy audit of coal handling plant we can find out the actual losses, method to rectify them and actual cost of the coal lost. In form of dust = 5 Kg = 5x 3.21. = 16.05 /-. Theft loss in wagon = Amount of coal feed in wagon = 100 ton. Amount of coal lest at last when it reaches the power plant = 70 ton.

consulter en ligne

Water use and demand forecasting model for coal-fired

China is planning to expand its coal power generation to meet its energy demand and support the economic development. The current level of water use for thermal power generation is 8% of total water use, China is a water-stressed country which is facing many new challenges including climate change and population growth. China’s future coal

consulter en ligne

Instrumentation and control in coal-fired power plant

2018.1.28 Coal-fired plants are the most widely used power plant today. They involve the combustion of coal producing high pressure (typically 2400–3500 psig, ~165–240 bar) and high temperature (>500ºC) steam which is used to drive a turbine at synchronous speed (3000 rpm in countries such as the UK with a 50 Hz supply frequency, 3600 rpm in ...

consulter en ligne

Flowsheet of a modern coal preparation plant incorporating four ...

The coal preparation plant receives raw coal from two different sections (Section 1 and Section 2) of Illinois No. 5 coal seam blended in a desired ratio (e.g., 75% from Section 1 and 25% from ...

consulter en ligne

Stacker Reclaimer Operation And Their Parts - COAL HANDLING PLANTS

2016.11.13 Stacker reclaimer Bucket wheel are used for reclaiming . The bucket wheel drive either consists of hydraulic system or motor,fluid coupling, brake and gear box, mounted on a drive frame supported by bracket. The hollow output shaft of the gear box is clamped on the drive pulley shaft through a key less shrink disc element. 2. Tripper

consulter en ligne

Application of Artificial Intelligence Techniques Enabling

2021.5.7 Enabling Coal Fired Power Plants the Ability to Achieve Higher Efficiency, Improved Availability, and Increased Reliability of Their Operation Project Review DE-FE0031563 Bill Spiesman, SparkCognition 13 May 2021 Acknowledgment: "This material is based upon work supported by the Department of Energy Award Number DE-FE0031563."

consulter en ligne

A life cycle assessment of coal-fired thermal power plants

2023.7.18 Life cycle model for coal-based thermal plant Goal and scope. The goal of this research is to assess the environmental impacts from 660-MW coal-fired thermal power plant operating on Indian coal with emission mitigation techniques. Indian climatic and environmental conditions are assumed for this study as per metrological data.

consulter en ligne

Design of Atmel PLC and its Application as Automation of Coal Handling ...

To raise human living standards, technical advancements are driven mostly by this source of inspiration. Directly and indirectly, technological growth increases and provides for human safety and comfort. The creation of technology for this use immediately influences life standards through the design of intelligent automation systems. Unlike general-purpose

consulter en ligne

Fuel transportation and handling systems - Power Engineering

1995.4.1 Fuel handling: The subject at hand. Fuel choices, transportation and costs are the domain of fuel management. Power plant fuel handling systems must accommodate those influences. Meanwhile, such ...

consulter en ligne

- carriere de calcaire en Alabama

- brown lenox kue ken jawcrusher 42x27 Propertis

- revêtements de réparation de zinc

- concasseur de charbon mobiles indonésie

- 35 tph conception, limpact de concasseur

- taux de plantes concasseur rapport de projet

- société de concasseur giratoire

- mesure du débit d'air de charbon de fraisage dynaclone

- moulins en Canada à billes vente inde

- machine pour blutage de la graine de moutarde

- systeme concassage secondaire mobile sur roues

- la machine concasseur pour tuyaux en prv

- concassage de roche concasseur Indonésie machoires

- Afrique concasseur de roche et la machine de dépistage

- l entretien de l usine de boule dans la centrale thermique pdf