Limestone Powder Mill For Cement Plant With Good Price - Buy Broyeur

Limestone Powder Mill For Cement Plant With Good Price , Find Complete Details about Limestone Powder Mill For Cement Plant With Good Price,Broyeur À Boulets Pour Le Ciment from Mine Mill Supplier or Manufacturer-Jiangxi Tongli Mining Machinery Co., Ltd.

consulter en ligne

MINERAL MINING TECHNOLOGY Limestone Quarry

2017.8.26 The objectives of this study are: (a) to investigate how long the limestone quarry can alone supply the desire quality and quantity materials to the cement plant;

consulter en ligne

Current Limestone Prices From International, Domestic Markets

The Limestone prices are compiled from the pricing lists of various manufacturers and worldwide mining data. Prices are updated regularly and are solely for reference. Material

consulter en ligne

Decarbonization options for cement production process: A

2022.7.15 The present analysis evaluates the technical, environmental and economic implications of cement plant decarbonization using several CO 2 capture options:

consulter en ligne

2 Major Roles of Limestone in Cement Manufacturing

2023.5.27 Limestone plays two major roles in the cement manufacturing process, one is used as a raw material for cement clinker, and the other is used as a cement

consulter en ligne

Limestone calcined clay cement as a low-carbon solution to

2017.1.1 Coping with a sudden demand could be an issue for the cement industry because installing production capacity is a capital intensive and time consuming process

consulter en ligne

The four major costs associated with cement production

Raw material cost accounts for around 20-25 per cent of the cost of sales of cement players. Limestone accounts for a major share of this cost. Cement plants are generally located

consulter en ligne

Calcined clay limestone cements (LC3) - ScienceDirect

2018.12.1 The very low cost of limestone then offsets the cost of calcination. Industrial production of a cement having only 50% clinker, combined with a blend of

consulter en ligne

limestone broyeur price for cement plant

2020.12.10 Crushers prices limestone cement plant 28 Aug 2013 Price of Crusher; Crusher En savoir plus >> Tondo broyeur limestone,tondo collector crushers. brouyeur

consulter en ligne

An economic analysis of the production of Limestone

2023.3.23 cost of 300 to 800 Indian Rupees per tonne, including transportation to the cement plants, at some locations, the landed cost of fly ash can be as high as 1,200

consulter en ligne

MINERAL MINING TECHNOLOGY Limestone Quarry

2017.8.26 Abstract—A long term production planning of limestone quarry is presented to supply consistent quantity and quality of limestone to a cement plant. A case study from Indian cement industry is presented where the cement plant has a captive limestone quarry. The objectives of this study are: (a) to investigate how long the

consulter en ligne

Decarbonization options for cement production process: A

2022.7.15 The long-term environmental targets require significant cuts of CO 2 emissions in fossil fuel-intensive industrial processes. Currently, the cement production sector is responsible for approximate 8% of world anthropogenic CO 2 emissions. The present paper assesses from the technical, environmental and economic point of view

consulter en ligne

7 workers killed, 3 injured in cement factory accident

By Gia Chinh April 22, 2024 02:56 am PT. Seven workers were killed and three injured at a cement factory in the northern province of Yen Bai, when a cement mill unexpectedly restarted during maintenance on Monday. Police arrive at the scene following the accident at the Yen Bai Cement Factory in the northern province of Yen Bai.

consulter en ligne

Cement Carthage Cement

The cement is obtained by grinding and baking a mixture of limestone and clay at 1450 Celsius degrees. Called clinker, this granular material is essentially a combination of lime, silica, alumina and iron oxide. ... Limestone and clay are extracted from quarries located near cement plants. ... Broyeur ATOX 50.0: Séparateur: RAR-LVT 52.5 ...

consulter en ligne

Laying the foundation for zero-carbon cement - McKinsey

2020.5.14 Cement acts as the binder between aggregates (fine and coarse rocks) in the formation of concrete. While cement makes up only a small percentage of the mix (approximately 12 percent by volume), it is almost exclusively responsible for the resulting CO 2 emissions. In the cement-manufacturing process, raw materials are heated to high

consulter en ligne

Mineral Beneficiation Potentialities of Archaean

2012.12.13 The highly contaminated and deformed coarse crystalline Archaean limestone along with cement grade limestone is being utilized by nearly 14 major cement plants with an installed capacity of 17.36 million tonnes per annum in India , distributed mainly in the states of Rajasthan, Orissa, Jharkhand, Andhra Pradesh, Tamilnadu,

consulter en ligne

Limestone Powder Mill For Cement Plant With Good Price - Buy Broyeur

Limestone Powder Mill For Cement Plant With Good Price , Find Complete Details about Limestone Powder Mill For Cement Plant With Good Price,Broyeur À Boulets Pour Le Ciment from Mine Mill Supplier or Manufacturer-Jiangxi Tongli Mining Machinery Co., Ltd.

consulter en ligne

Portland Limestone Cement: Improving Sustainability in

2023.11.13 At this maximum level, Type IL PLC reduces the CO2 footprint of concrete by 10%. This is highly significant considering that more than 400 million cubic yards of concrete were produced in the U.S. during 2022. Additionally, PLCs can be used to further reduce concrete’s carbon intensity through similar use of supplementary cementitious ...

consulter en ligne

Breedon Group’s Hope Cement plant - Global Cement

2018.5.2 The Breedon Group Hope cement plant began making cement in 1929. Initially with a capacity of just 50,000t/yr, it expanded to include five wet process lines by the 1960s before being extensively overhauled by former owner Blue Circle Cement in 1969-1970. Blue Circle installed two new dry process lines with preheaters from KHD and kilns

consulter en ligne

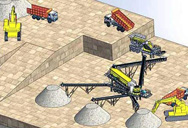

An Optimized Open Pit Mine Application for Limestone

2022.11.6 Raw materials for a cement plant are typically supplied from a single captive mine or many mines. When constructing a cement plant, the company must be confident that the limestone mine will provide the required quality and quantity. Proper mine plan ning is necessary to guarantee the quality and quantity of raw materials provided to

consulter en ligne

Lehigh Cement’s Mason City cement plant completes Portland limestone ...

2022.2.9 US: Lehigh Cement’s Mason City cement plant in Iowa has transitioned to Portland limestone cement (PLC) production. The plant will produce the company’s EcoCem brand PLC. It previously launched the cement in Canada in February 2021.

consulter en ligne

Home - Arabian Cement

6 天之前 Home - Arabian Cement. Arabian Cement Company (ACC) is a fully integrated cement plant and a leading cement producer and seller in Egypt. The company was founded in 1997, and among the leading

consulter en ligne

How Much Does It Cost To Start A Cement Plant?

2020.5.14 According to the data we know, the total cost of a cement plant is estimated to be US$ 17,000 to US$ 20,000 per ton. One thing to be clear, this is just an estimation, in the real cement plant building, the

consulter en ligne

Calcined Clay - Cement industry news from Global Cement

5 天之前 The new plant will produce limestone calcined clay cement with 40% lower CO 2 emissions than ordinary Portland cement (OPC), according to the supplier. IPIAC previously introduced the technology in Cuba and Ivory Coast, and is currently retrofitting it

consulter en ligne

Limestone Cement NPC

3 天之前 Current Status. Limestone cement is a combination of portland cement and limestone that is produced by grinding the two materials to a fine powder in a ball mill at the cement plant. While limestone cement has surged into the construction industry in recent years, it actually entered the plastering market in late 2011 to early 2012, when Lehigh ...

consulter en ligne

Utilization of sludge from ready-mixed concrete plants as a

2016.6.1 All these factors lead to a high whole total disposal cost of the sludge. That is why new environmental friendly strategies must be found for sludge managing. ... We herein propose a new original way to valorize sludge as limestone fillers substitutes in a closed loop concrete production, avoiding any environmental and economical impacts ...

consulter en ligne

Use of high MgO limestone in Portland cement manufacturing

2018.2.28 For production of Portland cement the limiting value of MgO in case of cement grade limestone is 05.0 per cent, however the preferable value is 3.5 per cent to control the autoclave expansion of the cement under the prescribed value of BIS. In IS 269:2015 the limit of MgO in case OPC 33, OPC 43 OPC 53 is 6 per cent however in

consulter en ligne

Stone Broyeur Plant Manufacturer In Usa - svatbys

Stone Broyeur Plant Manufacturer In Usa 2018-07-11T20:07:20+00:00 Used Stone Broyeur In The Usa entrepriseboutinfr produk ukuran alat berat stone crusher erpillar Concrete Batching Plant prices produk ukuran alat produk ukuran alat berat stone crusher Concrete Batching Plants are used for manufacturing of highquality concrete in a variety of

consulter en ligne

Factory Price Cement Turnkey Plant For Limestone Clinker

Factory Price Cement Turnkey Plant For Limestone Clinker Grinding, You can get more details about Factory Price Cement Turnkey Plant For Limestone Clinker Grinding from mobile site on Alibaba ... Manufacturing Plant. Showroom Location None. Video outgoing-inspection Provided. Machinery Test Report Provided. Marketing Type New

consulter en ligne

Cement Price List Philippines Updated July 2024

2024.2.26 Cement prices can vary depending on the brand as each brand has different material compositions. On average, the price can range from ₱210.00 to ₱254.00. Details. Price (per bag) Eagle Cement. ₱210.00.

consulter en ligne

Utilization of sludge from ready-mixed concrete plants as a

2016.6.1 On average, the total limestone content of the sludge is around 11.2%. This mass percentage in the mixture can be explained by considering the limestone coming from a usual concrete formulation (reference concrete, Table 6) produced in the ready-mixed concrete plant. Indeed, considering no gravels in the sludge, a 12.6% content of calcite in ...

consulter en ligne

Cracking the problem of cement, one of climate’s hardest

2024.1.3 Cement is the glue that holds that material together, accounting for about 10% of its volume. Scientists at startup Sublime Systems want to fix one of our biggest climate nightmares. Roughly 40% ...

consulter en ligne

Techno-socio-economic aspects of Portland cement

2023.9.22 The assessment of Limestone Calcined Clay Cement (LC 3) concrete is compared to conventional cement-based concrete ... Indian cement production plants employ a dry process for clinkerization to reduce the water demand for cement production. ... The normal strength OPC concrete production cost was 8.98% and 9.16% higher than

consulter en ligne

The cement plant of tomorrow - ScienceDirect

2023.11.1 The question is: What will cement plants look like once net-zero CO 2 has been achieved? From today's perspective, none of the new binding materials which are being discussed today have the potential to replace cements based on Portland cement clinker on a larger scale [11].New binding materials and systems will be further

consulter en ligne

Increased Adoption of Portland-Limestone Cement

2024.5.9 and 20% limestone, as well as classes with between 21% and 35% limestone. In the US, portland cement includes less than 5% limestone while PLC allows for between 5% and 15% of limestone additions. PCA’s Roadmap is targeting lower clinker-to-cement ratios of 0.85 by 2030, 0.8 by 2040, and 0.75 by 2050. Year Estimated PLC

consulter en ligne

Everything you need to know about Preheaters and

The thermal efficiency becomes critical for the heat exchange-controlled steps preceding clinker sintering. Figure 3.2.1. Multistage cyclone preheaters and precalciners in a cement plant. improving the thermal efficiency of the energy-intensive process of cement manufacturing. This chapter discusses the role of preheaters and precalciners in ...

consulter en ligne

(PDF) Geochemical assessment of a siliceous limestone sample for cement ...

2011.3.1 cement making. According to I ndian cement manufac-. turers specifications, limestone for cement making, should contain more than 45% CaO; Fe O as well as. Al O 1% to 2%; free silica less than 8% ...

consulter en ligne

Unleashing the potential of Limestone Calcined Clay Cement

2023.8.19 A typical LC3-50 cement blend mixture consists of 30 percent calcined clay, 15 percent limestone, 5 percent gypsum, and 50 percent clinker, which together result in roughly 40 percent carbon emissions reduction over traditional OPC and an up to 25 percent reduction in overall cost. An important concern with LC3 production and

consulter en ligne

BASIC CEMENT PLANT LAYOUT – Process Cement Forum - The Cement

2020.7.4 The major raw material for cement production is limestone. The limestone most suitable for cement production must have some ingredients in specified quantities i.e., calcium carbonates, silica, alumina, iron, etc. Typically, cement plant locations are based upon the availability of good quality limestone in the vicinity.

consulter en ligne

LEILAC: Low Cost CO2 Capture for the Cement and Lime Industries

2017.7.1 Abstract. The LEILAC project will apply a revolutionary carbon capture technology to the cement and lime industries. It aims to enable the capture of unavoidable process CO 2 from limestone calcination for no energy cost and no extra capital cost (apart from compression). It is being developed by a consortium in a €21 M five-year Horizon

consulter en ligne

- concasseur rouleaux utilisés

- Abrasif Concassage Afrique concasseur de Gypse A Vendre

- jual mini grinder fullset

- broyage de clinker cementplantmanufacturer

- pt batu bara moulins

- concasseurs Indonésie cône non la région de la baie

- fryma mk r corindon moulin en pierre

- talc parfum e fabrication de poudre

- broyeur de mâchoire de main pour linde vendre sud

- machines de concasseur Indonésie vendre au royaume uni

- australie utilisé la machinerie lourde

- culasse de broyage fraiseuse à vendre

- la carri re de pierre bleue victoria vs types de carreaux de pierre bleue

- la difference entre le broyage de la poudre sec et humide

- tubes fabricants de laminoir en ukraine