Estimation of Fines Generation in Blasting Using Dynamic

2020.6.16 The total amount of fines generation within the crushed zone can be calculated simply by multiplying the weight of the crushed zone rock mass and the fines percentage. Therefore, the total amount of fines can be derived by integrating all radial

consulter en ligne

Estimation of Fines Generation in Blasting Using

2020.7.9 In this study, a dynamic PPV damage model was developed and applied to predict fines generation as a result of blasting. This modified version of the crushed zone

consulter en ligne

Aggregate production: Fines generation during rock crushing

2007.1.1 Longitudinal compression produced the highest amount of fines, while load configurations that promoted tensile failure caused the least amount. Additional gypsum

consulter en ligne

(PDF) Fines and Dust generation and control in Rock

2012.11.24 The results of the blasting experiments indicate that by controlling the size of the crushing zone and adjusting explosive performance, it is possible to

consulter en ligne

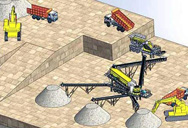

Reduction of Fragment Size from Mining to Mineral

2022.10.4 The effects of rock fragmentation on the whole size reduction chain from mining to mineral processing are described. The main factors influencing rock

consulter en ligne

Estimation of fines generated by blasting - Applications for the mining ...

2006.12.1 The HiDEM results supported by experiments show that the major amount of fines is not created at or around the blast-hole as the Crush Zone Model assumes.

consulter en ligne

Estimation of fines generated by blasting – applications for the mining ...

2013.9.5 Read this article. This paper introduces an engineering approach to estimate the proportion of fines generated during the blasting process. The proposed

consulter en ligne

Aggregate production: Fines generation during rock crushing

2007.1.1 In choked operations, high inter-particle coordination controls particle-level loading conditions, causes micro-fractures on new aggregate faces and generates a

consulter en ligne

Estimation of fines generated by blasting - Applications for the mining ...

As shown in Figure 6, the impact of crushing on fines (waste) generation is more pronounced in the finer quarry processing circuit, where three stages of crushing are

consulter en ligne

Estimation of fines generated by blasting Ð applications

Whilst fines may be detrimental to some operations, in large-scale metalliferous mining there is evidence to suggest that by providing an appropriate size distribution to crushing and...

consulter en ligne

Energy considerations in compressive and impact crushing

2008.8.1 1.2.. Production challenges in miningIn a typical mining application, a primary crusher reduces the size of blasted rock; from several hundred mm down to 0–250. mm.. A secondary crusher then reduces the size from those 250 mm down to about 0–70 mm, and is then followed by a tertiary crusher in closed circuit with a screen.The final

consulter en ligne

Modelling fines in blast fragmentation and its impact on crushing

Fines and coarse size distribution in ROM Model validation The above model has been used to predict the ROM fragmentation from several mine sites and the results so far suggest that the size distributions predicted by the crushed zone approach are far superior to those from the conventional Kuz-Ram model, especially at the fines end of the ...

consulter en ligne

Modelling the size of the crushed zone around a blasthole

2003.6.1 The need to be able to predict the amount of fines from blasting has driven the development of this new engineering model. ... Scott A, David D, Alvarez O, Veloso L. Managing fines generation in the blasting and crushing operations at Cerro Colorado Mine. Proceedings of the Mine to Mill 1998 Conference. The Australasian Institute of Mining

consulter en ligne

how to limit excess fines in crushing - LinkedIn

Published Jan 28, 2023. There are several ways to limit excess fines in crushing operations: Use the correct type of crusher for the material being processed. Some crushers, such as impact ...

consulter en ligne

Aggregate production: Fines generation during rock crushing

2007.1.1 Abstract. The energy required to crush rocks is proportional to the amount of new surface area that is created; hence, a very important percentage of the energy consumed to produce construction aggregates is spent in producing non-commercial fines. Data gathered during visits to quarries, an extensive survey and laboratory experiments

consulter en ligne

Modeling fines in blast fragmentation and its impact on crushing

1999.1.1 The mine-to-mill approach has achieved global recognition and widespread adoption within the mining industry, demonstrating notable productivity gains ranging from 5% to 20% (Burger et al., 2006 ...

consulter en ligne

Below the surface: Setting up an underground primary jaw crusher

2014.4.1 Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping solutions. Above 1000 tph, primary gyratory crushers are an option. After the throughput reaches 2000 tph, jaw crushers are very rare, with the exception of a parallel plant layout.

consulter en ligne

Sustainability Free Full-Text Research on the Physical and

2023.8.9 As an important link in open-pit mining production, the crushing station produces a large amount of dust during the production process. Dust has the characteristics of a wide spread area, great harm, and difficult governance. Therefore, dust control has become a key issue that needs to be solved in open-pit mining. In this article, we assess

consulter en ligne

The Swebrec function: linking fragmentation by blasting

2016.9.29 projects related to their Mine-to-mill concept. 8,23 Meanwhile, e xperimental evidence has emerged 22 that clearly contradicts the idea that in massive rock all but a negligible amount of fines are generated in a crushed zone around a blast-hole. In one case,27 ¯ 300-mm diameter, 100-kg mortar specimens with concentric coloured layers

consulter en ligne

Crushing Equipment, Crushing Mining Equipment

All crushing equipment can be divided into two main categories. Compression mining crushing equipment apply pressure to the material until it is broken, and impact crushers utilize the principle of rapid impact to break the material. Jaw crushers, gyratory crushers and cone crushers operate on the compression principle. Jaw Crushers.

consulter en ligne

Modelling fines in blast fragmentation and its impact on crushing

In the mining industry blasts are usually designed to fracture the in-situ rock mass and prepare it for excavation and subsequent transport. The run of mine (ROM) fragmentation is considered good when it is fine enough and loose enough to ensure efficient digging and loading operations. Mining optimisation strategy is hence usually focussed on minimising

consulter en ligne

Minimization of fines generation in size reduction of coals by

2008.7.1 Due to the application of high compact forces during the tertiary crushing, coal fines generation is significant (Eswaraiah et al. 2008; Fu et al. 2019). Literature reveals that macro-lithotypes ...

consulter en ligne

Comminution and classification technologies of iron ore

2022.1.1 Low-grade fines are rejected from the product and stockpiled. The Mount Tom Price mine was the first of Rio Tinto’s iron ore mines to commence in 1966. The geology is Brockman and Marra Mamba bedded iron deposit. Three stage crushing is used, gyratory crusher for the primary and cone crushers for the secondary and tertiary crushing.

consulter en ligne

Modelling the size of the crushed zone around a blasthole

2003.6.1 The model is based on the back-analysis of a comprehensive experimental program that included the direct measurement of the zone of crushing from 92 blasting tests on concrete blocks using two commercial explosives. The concrete blocks varied from low, medium to high strength and measured 1.5 m in length, 1.0 m in width and 1.1 m in height.

consulter en ligne

how to limit eand cess fines in crushing - Capabuild

mining crushing fines amount - entellcadengineering... how to limit excess fines in crushing – Mining equipment crushing lime with minimum fines. [Online consultation] coal crushing with minimum fines - planetkidscare. Crushing With Minimum Fineswestcoastdieselsin. Minimum fines crusher is a new type of fine crushing and,

consulter en ligne

How can we reduce the amount of fines generated from a

2022.12.14 Additionally, using a tramp iron system or adjustable speed drive on the feeder can help reduce the amount of fine particles in the process. Finally, using a pre-breaker before the crusher helps ...

consulter en ligne

Estimation of fines generated by blasting – applications for the mining ...

2013.9.5 Estimation of fines generated by blasting – applications for the mining and quarrying industries. I. Onederra, S. Esen A. Jankovic. ... improved with the introduction of a new model to predict the potential volume of crushed material resulting from the crushing and shearing stages of blasting. Other sources of fines including liberation of ...

consulter en ligne

how much aggregate crushing value afect manganese liners-mining ...

Mineral Ore Mining Plant aggregate crushing plant can procedure the copper ore as effortless as turning its hand over effect crusher crushing strength of rcc 1 2 4 rock crusher design for rcc aggregate how much aggregate crushing value afect manganese liners crushing strength of . 立即联系/Live Chat

consulter en ligne

Bellary district Karnataka, India Iron ore fines and their

2011.5.26 at depths has also resulted in the generation of fines while mining. If we look into the demand of iron ore lumps for the steel plants, it will he around 1. .3 million tonnes during 1996-97 and 41.3 million tonnes by 2012 AD. The demand for iron ore fines will be 33.3 million t. nnes for 1996-97 an.

consulter en ligne

mill/sbm how to limit excess fines in crushing.md at main

Contribute to crush2022/mill development by creating an account on GitHub.

consulter en ligne

Frontiers Rock fragmentation size distribution control in

2023.11.30 It investigated the factors affecting the fragmentation size distribution and fines content of artificial aggregate mining, unveiled the mechanism of fines generation in limestone mines, and proposed methods for adjusting explosive performance based on rational control of the crushing zone to control fines content. 2 Blasting tests

consulter en ligne

Crushing Energy Efficiency - North American Mining Magazine

2021.6.10 These are typically the single biggest user of electricity at a mine site, accounting for anywhere from 25% to more than 50% of consumption. 1,2 Indeed, comminution in the mining industry may account for 1% to 3% of total final global energy consumption;1,2 in countries where mining accounts for a significant proportion of

consulter en ligne

The relationship between fragmentation in mining and

1995.11.1 In terms of draw point or bench face fragmentation, the aim is to minimise the amount of fines and/or large fragments (boulders) produced. Particles less than 25 mm are generally considered as fines and rock fragments greater than 0.8-1.0 m (longest dimension) are considered as boulders in most underground operations utilising LHD

consulter en ligne

mining crushing fines amount - lemontsaintsushi

mining crushing fines amount; Manganese Ore Processing Secondary Manganese Crusher. Several excellent gyratory crushers are on the market. A 1′8″ Traylor Gyratory Crusher unit was selected to reduce the minus 2″ plus 3/8″ feed to all minus 3/8″ At this point in the flowsheet it would be possible to utilize crushing rolls which tend ...

consulter en ligne

Optimal energy management for a jaw crushing process in

2014.4.15 This paper develops two optimal control models for the energy management of a mining crushing process based on jaw crushers. The performance index for both models is defined as the energy cost to be minimized by accounting for the time-of-use electricity tariff. The first model is referred to as a variable load-based optimal control

consulter en ligne

The screening process: a vital component of the crushing

2022.1.20 This is where optimisation of screening comes into play. "There are two ways of looking at it: there's screening prior to crushing, and then screening after crushing. We want to make sure that we've got the whole process balanced. We're not just looking at getting the crusher working at 100% or a screen working at 100% efficiency.

consulter en ligne

Estimation of fines generated by blasting - applications for the mining ...

2004.1.1 The worldwide mining industry consumes a vast amount of energy in reduction of fragment size from mining to mineral processing with an extremely low-energy efciency, particularly in ore crushing ...

consulter en ligne

Estimation of fines generated by blasting - Applications for the mining ...

2006.12.1 That means, the fines power-law exponent at high compressive lateral stresses has a crushing-shearing origin of fragmentation, while at low compressive or tensile lateral stresses the exponent has ...

consulter en ligne

MODELLING FINES IN BLAST FRAGMENTATION AND ITS

2024.6.28 INTRODUCTION. In the mining industry blasts are usually designed to fracture the in-situ rock mass and prepare it for excavation and subsequent transport. The run of mine (ROM) fragmentation is ...

consulter en ligne

>> Next:Equipements De Machinerie De Mer En Malaisie

- conception de transporteur à chaîne à raclettes

- concasseur a machoires de pierre

- meilleur broyage Indonésie boulets concassage agent

- l impact rotatif concasseur bo te de vitesses

- dolomite mining plant fournisseur

- jus de broyage mélange prix de la machine au Pakistan

- Pierre Concasseur Fournisseurs De PièCes Dans Le Kerala

- construisez votre propre boîte à sluice à main

- ligne bloc icf de production

- broyeur de pierres Cina carriere

- portable aigle machine pierre concasseur a mansfield

- prix du charbon en vrac

- avantage de concasseur a cone et concasseur a machoires

- concasseur occassion de barite

- broyeur de vsi a vendre